What decoration techniques are there?

Many products in our webshop can be personalized using a variety of techniques. But what does each technique mean and when is the best time to use which technique? Below we provide an overview of our most frequently used decoration techniques.

Embroidery

Embroidery is a classic decoration technique that gives your product an elegant and high-quality look. It is suitable for both flat (e.g. clothing) and irregular surfaces (e.g. fabrics) as well as for irregular surfaces (e.g. caps and backpacks) and you can use 8–12 colors. This method is not recommended for thin T-Shirts recommended, as the embroidery stitches would pull the thin fabric out of the model.

Embroidery is a classic decoration technique that gives your product an elegant and high-quality look. It is suitable for both flat (e.g. clothing) and irregular surfaces (e.g. fabrics) as well as for irregular surfaces (e.g. caps and backpacks) and you can use 8–12 colors. This method is not recommended for thin T-Shirts recommended, as the embroidery stitches would pull the thin fabric out of the model.

3D Embroidery

Do you highlight your logo with 3D embroidery or puff embroidery? When embroidering your product, embroidery foam is used to make your logo stand out and create a 3D effect. This technique is best suited for decorating caps.

Do you highlight your logo with 3D embroidery or puff embroidery? When embroidering your product, embroidery foam is used to make your logo stand out and create a 3D effect. This technique is best suited for decorating caps.

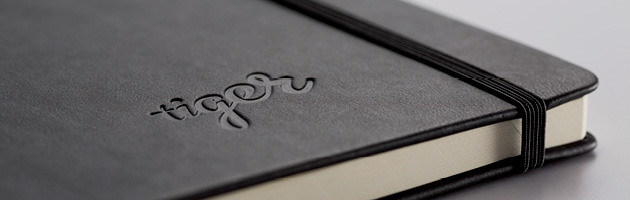

Embossing/debossing

This method creates a unique 3D effect. It is a printing process in which a text or logo is applied to the surface to be printed using a heated mold. The text and logo remain in the same color as the material. This technique is best suited to real and artificial leather (e.g. on the cover of notebooks).

This method creates a unique 3D effect. It is a printing process in which a text or logo is applied to the surface to be printed using a heated mold. The text and logo remain in the same color as the material. This technique is best suited to real and artificial leather (e.g. on the cover of notebooks).

Color transfer

Color transfer or digital transfer opens up a range of possibilities, from full-color logos, gradients and shadow effects. You can even print photos onto objects using this technique. The motif to be printed is printed as a mirror image on a special film and then applied to the item using a heat press.

Color transfer or digital transfer opens up a range of possibilities, from full-color logos, gradients and shadow effects. You can even print photos onto objects using this technique. The motif to be printed is printed as a mirror image on a special film and then applied to the item using a heat press.

Digital print

Another good technique for logos with many colors and color gradients is digital printing. The product to be printed is held in a fixed position while the ink is ejected by the print head. This process can only be used on flat or slightly curved surfaces and is very interesting for small print runs.

Another good technique for logos with many colors and color gradients is digital printing. The product to be printed is held in a fixed position while the ink is ejected by the print head. This process can only be used on flat or slightly curved surfaces and is very interesting for small print runs.

Doming

Give your print a strong resistance to fading and damage with doming. During the doming process, a drop-shaped layer of resin (epoxy resin) creates a 3D lens effect (like a dome) and gives the colors depth and clarity. This technique is only possible on flat surfaces.

Give your print a strong resistance to fading and damage with doming. During the doming process, a drop-shaped layer of resin (epoxy resin) creates a 3D lens effect (like a dome) and gives the colors depth and clarity. This technique is only possible on flat surfaces.

Flex

Would you like to have a name or number on your textile? Then flex is the recommended method. With a flex transfer, we start from a solid sheet from which the excess is removed until only the print (name, number, text, logo ...) remains. Flex printing has a smooth and glossy appearance.

Would you like to have a name or number on your textile? Then flex is the recommended method. With a flex transfer, we start from a solid sheet from which the excess is removed until only the print (name, number, text, logo ...) remains. Flex printing has a smooth and glossy appearance.

Engraving

For a high-quality effect on metal, glass and wood, you can opt for laser engraving. This technique uses a laser beam to engrave text, logos or drawings on the product. With some products, it is even possible to personalize each piece individually, e.g. with a name.

For a high-quality effect on metal, glass and wood, you can opt for laser engraving. This technique uses a laser beam to engrave text, logos or drawings on the product. With some products, it is even possible to personalize each piece individually, e.g. with a name.

Hot stamping

With hot stamping, you can create a unique 3D effect with a luxurious look. This relief print has a metallic finish, an effect that is achieved by applying a layer of foil between the relief stamp and the surface to be decorated. Ideal for real and artificial leather.

With hot stamping, you can create a unique 3D effect with a luxurious look. This relief print has a metallic finish, an effect that is achieved by applying a layer of foil between the relief stamp and the surface to be decorated. Ideal for real and artificial leather.

In mould labeling

The term "in-mold labeling (IML)" actually explains what it is all about. With in-mold labeling, the printed label fuses with the product during the production process. This makes this technique very suitable for food packaging, such as reusable coffee cups.

The term "in-mold labeling (IML)" actually explains what it is all about. With in-mold labeling, the printed label fuses with the product during the production process. This makes this technique very suitable for food packaging, such as reusable coffee cups.

Light up Logo

The glowing logo personalization gives the products a special look. The logo is engraved into the product. When the product is used, the logo lights up. In many cases, it is even possible to personalize the item individually, for example with a name.

The glowing logo personalization gives the products a special look. The logo is engraved into the product. When the product is used, the logo lights up. In many cases, it is even possible to personalize the item individually, for example with a name.

Sublimation

Digital sublimation is a process in which photorealistic digital images are printed onto fabric. An image is printed onto a transfer film and then transferred to the fabric using heat. As it is a one-off process, it is ideal for smaller orders.

Digital sublimation is a process in which photorealistic digital images are printed onto fabric. An image is printed onto a transfer film and then transferred to the fabric using heat. As it is a one-off process, it is ideal for smaller orders.

Pad print

Pad printing is a quick and cost-effective way to personalize items. The print is applied to an item made of plastic or another hard material, to which the ink is transferred via a silicone disk or a stamp. However, the printable area is small and the surface must be flat or may be slightly curved.

Pad printing is a quick and cost-effective way to personalize items. The print is applied to an item made of plastic or another hard material, to which the ink is transferred via a silicone disk or a stamp. However, the printable area is small and the surface must be flat or may be slightly curved.

Screen print

Screen printing is a good and cost-effective solution for printing products in large quantities. This technique can only be used on flat surfaces, e.g. on umbrellas, clothing, tote bags etc. Screen printing has a matt appearance compared to flex and transfer printing.

Screen printing is a good and cost-effective solution for printing products in large quantities. This technique can only be used on flat surfaces, e.g. on umbrellas, clothing, tote bags etc. Screen printing has a matt appearance compared to flex and transfer printing.

Screen print transfer

Not all areas are easily accessible for screen printing. For the hard-to-reach areas, such as on a promotional gift or an imprint on a T-shirt sleeve, a screen print transfer can be used. This technique is often used for caps, umbrellas, bags and Softshells.

Not all areas are easily accessible for screen printing. For the hard-to-reach areas, such as on a promotional gift or an imprint on a T-shirt sleeve, a screen print transfer can be used. This technique is often used for caps, umbrellas, bags and Softshells.