The difference between RGB, CMYK and PMS

Colors are an important aspect of printing, but not all colors are the same. There are different color models (types of colors). The most important color models are RGB, CMYK and PMS.

RGB

RGB colors (Red Green Blue) mainly occur in digital media, like your monitor or pictures you make with a digital camera.

With RGB, the starting point is 'light'. The more light that is produced, the more color that can be seen. Without any light, there is no noticeable color, also known as black. The easiest example is your monitor. If it doesn't produce any light, all you see is black. The more light your monitor produces, the brighter the colors will be, and if the monitor produces Red, Green and Blue at their maximum levels and they are mixed together, you'll see white.

The color consists of a combination of the three base colors, red, green and blue. The amount of each color is between 00 (none of that color) and the hexadecimal FF (all of the color). In total, you can create 16.777.216 colors.

Unfortunately, RGB colors can't be printed, since paper doesn't produce any light. Paper absorbs and reflects light that is emitted by another light source such as the sun, your desk lamp or your monitor. In order to print RGB colors we must convert the additive color model (RGB) to a subtractive color model (CMYK).

CMYK

CMYK colors are composed of four base colors: Cyan, Magenta, Yellow and Key (Black). Just like RGB, colors are formed by combining these four base colors. A first difference is that the surface/background with CMYK is white (e.g. the paper). This is why we need the "Key" color to make a beautiful, deep black. In addition, paper absorbs and reflects light as opposed to a monitor that emits light. Because of this, we use inks that partially absorb the light. Only the unabsorbed light is reflected. This means that the color of the paper itself is also a very important factor in the way colors are perceived. CMYK colors don't just absorb the light that is reflected by the paper, but they are also influenced by the color of the paper. An identical picture printed on white paper will be perceived differently than one printed on recycled or salmon-colored paper.

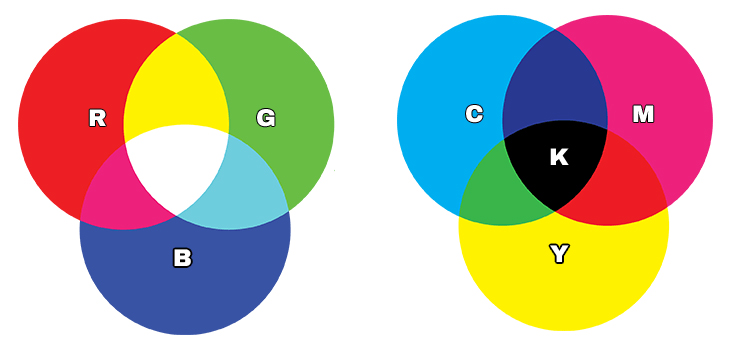

Figure 1 shows that RGB colors are combined to get more colors. CMYK only passes the ink color, all other light is partially or completely absorbed. With RGB, we work with light sources of colors, CMYK is based on color filters.

Figure 1: Color models RGB and CMYK

Another important difference is that you can't form that many different colors with CMYK. This leads to colors that you can see on your screen, but can't be printed. These differences in color mainly affect brown, green and purple shades and most of all very bright colors. The biggest differences occur with a combination of both, e.g. a bright, poison-green color.

Therefore it is very important that files are created with the correct color coding. If your file is created in RGB, it can be converted to CMYK. Please realise that colors that are not in the CMYK spectrum will be converted to the closest color that can be printed, which can cause unpleasant surprises. You can read here how to ensure that your file is in the correct color coding.

Most products like posters, flyers, banners, business cards, ... are printed in CMYK, also known as 4-color, full-color or quadri print. For promotional products (e.g. pens, sunglasses, etc.) and textile items (e.g. t-shirts, sweaters, etc.) we usually don't use CMYK colors; PMS colors are used instead.

Note: If you have stickers with transparent background printed in CMYK, the white color in your design becomes transparent on the sticker.

PMS

PMS stands for Pantone Matching System and consists of 18 base colors that can be combined to 1.124 mix colors. PMS colors are a globally used standard. This allows everyone to guarantee the match between the desired color and the ink color, which can differ if you don't use PMS color.

Note: the color of the ink that represents a PMS color is always the same. However, this does not mean that the colors will look the same on each product. The underlying material can absorb the ink in different ways, resulting in a color difference.

PMS colors can also be used for products other than promotional items and textiles. For example, PMS colors are also used for printing spot colors. These are generally very important colors that must always be as identical as possible everywhere (e.g. the red tint of the Coca-Cola logo). This can only be achieved by using PMS colors.

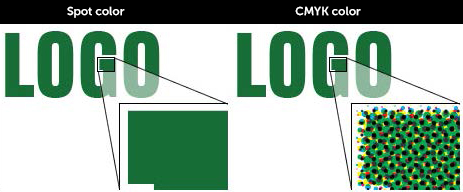

Figure 2: Spotcolor vs CMYK colors

In figure 2 you can see the difference between a spot color and a CMYK color. This picture shows why it is difficult to achieve a specific color and keep it consistent in every print job when using CMYK. During the production process CMYK colors are printed onto the material one by one, in so-called print towers. PMS colors are mixed into the desired color prior to the production process.